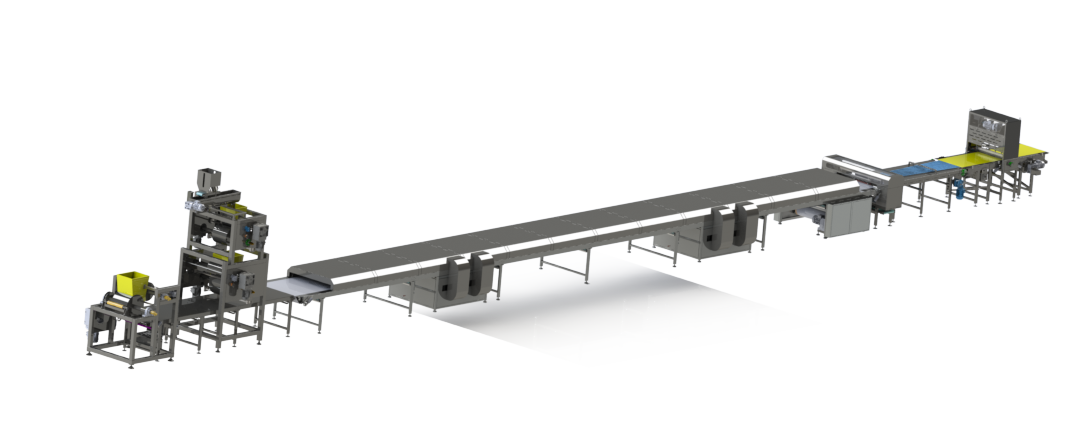

FORMALISING

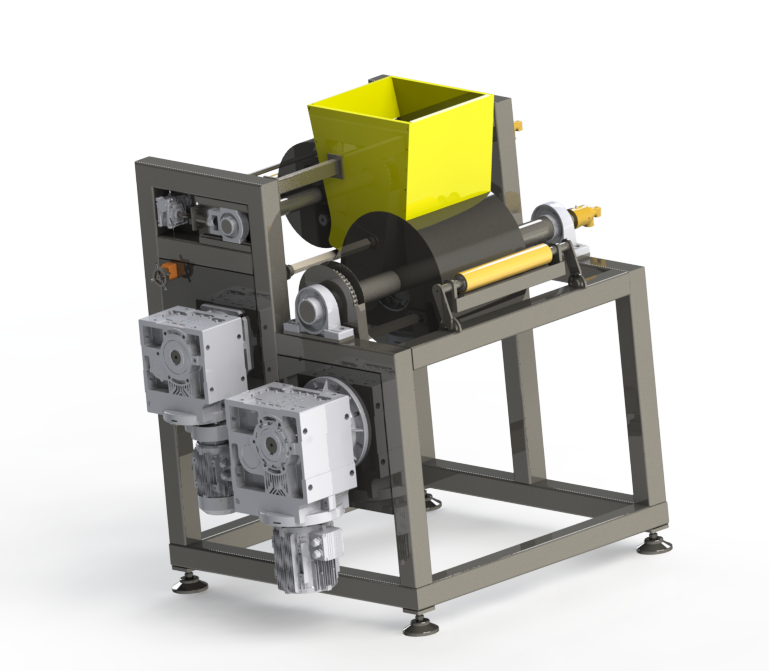

NOUGAT CYLINDERS

Nougat

cylinders are used in order to shape the nougat dough, which is brought to the

desired density and a homogeneous structure in the solid mixer. The product

coming to the nougat cylinders has a certain temperature. The temperature of

the product is lowered by the cold water coming from the chillers and entering

the cylinders.

There are oil

chambers to lubricate the surface of the nougat cylinders. The big cylinder is

fixed and the small cylinder is movable to adjust the thickness. Each roller

has a stainless steel scraper blade. To prevent nougat from sticking, the

surface of the blades are covered with teflon.

The surface

of the rollers is plated with ground hard chrome. The parts touching product

are made of suitable material for food. Chasis is made of ST-37 material and

painted.

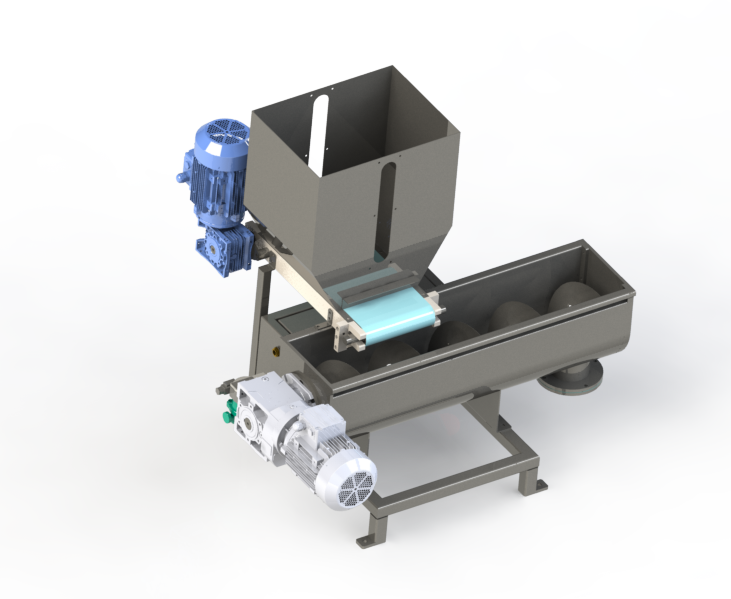

CARAMEL CYLINDERS

Caramel

rollers consist of two groups. While the user who only wants to work with

caramel can use only the lower group, when it is desired to mix an additional

material such as hazelnut-pistachio, he should also use the upper group

together with the hazelnut spiral.

The surface

of the rollers is ground and hard chrome plated. The parts touching product are

made of suitable material for food. Chasis is made of ST-37 material and

painted.

NUTS HELIX

The hazelnut

spiral is a machine designed to mix products such as hazelnut-pistachio

homogeneously into the caramel product and can be mounted on the caramel

cylinders chassis. It contains a helix and a nut-pistachio reservoir and band

group on it. The hazelnut-pistachio auger is produced entirely from 304 chrome

stainless steel.

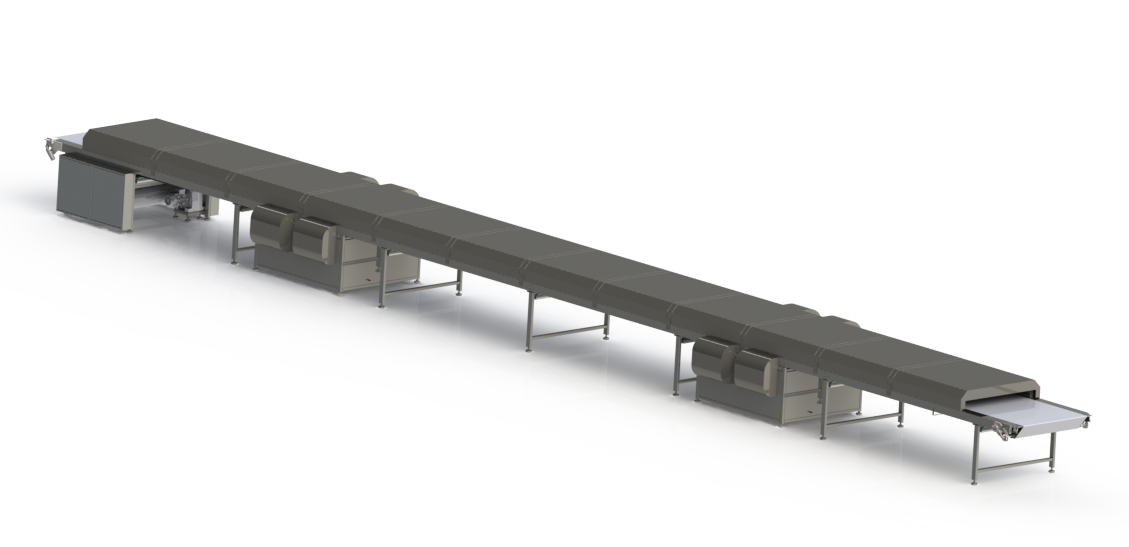

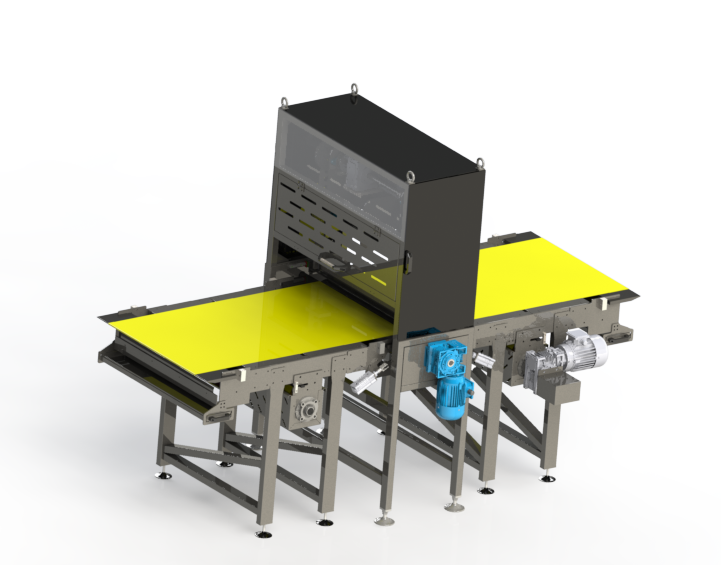

COOLING TUNNEL (BASE COOLED)

It is a

machine made of stainless materials with a polyurethane band used to reduce the

temperature of the product inside the cooling tunnel to the desired values.

The band is a

polyurethane tape suitable for food with a thickness of 1.2 mm in the desired

width. There is 6 meters-opened area at the entrance of the tunnel to spread

caramel and nougat out on it. The inner

and outer parts of the tunnel made of stainless steel.

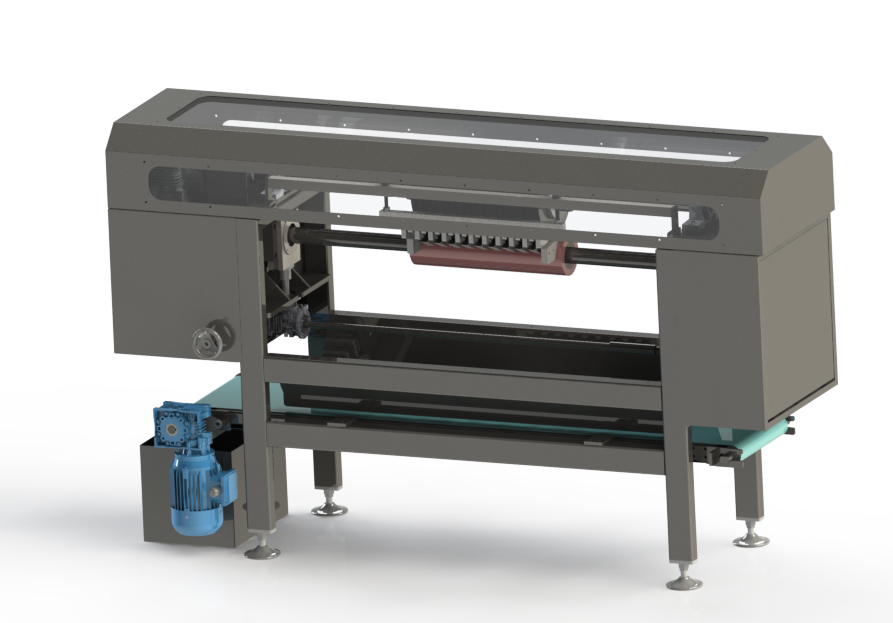

SLICING

A slicing

machine is needed to slice the nougat product with reduced temperature coming

out of the cooling tunnel in desired sizes. With this slicing, the width of the

product is determined. Since the machine dimensions are small, it takes up very

little space.

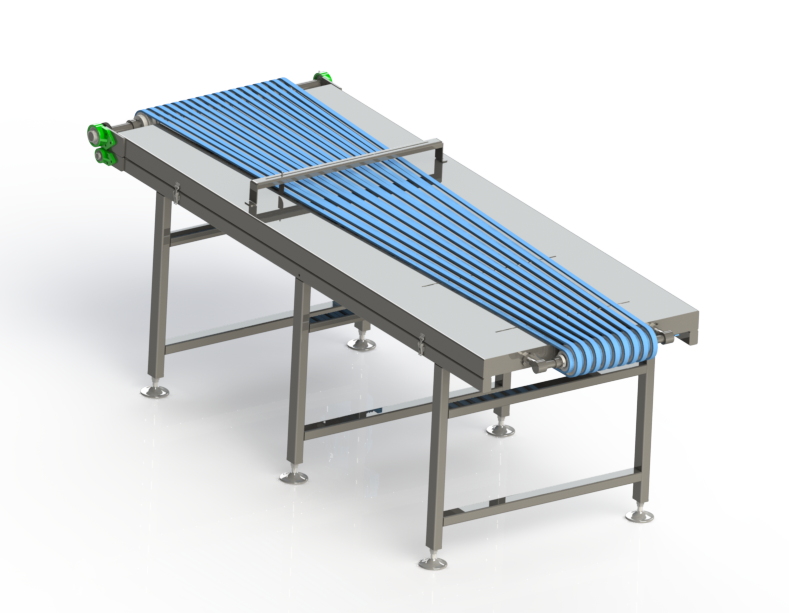

SEPERATION TABLE

A separating

table is used to open the gaps of the product separated in the slicing machine.

The band of each product is separate. It is designed in such a way that the top

table can be easily changed when the product dimensions will change. The

product band is produced from food-grade polyurethane material. The separation

table is completely made of stainless chrome material.

GUILLOTINE CUTTING

A guillotine

cutting machine is used to cut the length of the product sliced in the slicing

machine. The length of the product whose width is determined in the slicing

machine is determined in this machine.

Guillotine

cutting is done under servo motor control. The size of the product can be

precisely adjusted to the desired dimensions.