NUGA KITCHEN

SYRUP PREPARING TANK

It is the machine where the nougat product is collected completely and

mixed homogeneously at a certain temperature. The products coming from the

glucose tank and sugar auger are collected in this boiler.

The outer part of the boiler is heat-walled. Stainless anchors inside

rotate at a certain speed, ensuring the homogeneity of the product. The

tank is completely made of stainless steel material

SYRUP USAGE TANK

The product prepared for use in the

syrup preparation tank is taken into this tank. In this tank, it is mixed

continuously with stainless

anchors at a certain temperature to

maintain its homogeneity.The outer part of the boiler is heat-walled. Stainless

anchors inside rotate at

a certain speed, ensuring the

homogeneity of the product.The syrup preparation tank is completely made of

stainless steel material.

The glucose product is kept in this tank, ready for use, by being mixed

continuously with a certain temperature The bottom part of the boiler is

produced convex to facilitate the product flow. The glucose tank is completely made of stainless steel material.

The outer part of the boiler

is heat-walled. Stainless anchors inside rotate at a certain speed, ensuring

the homogeneity of the product. After the product in the boiler is used and

the work is completed, the inside of the boiler and the transfer pipes can be

washed.

A sugar spiral is used to transfer the sugar used to prepare the nougat

product to prepare syrup. The sugar auger is a machine designed to raise the

sugar in a bowl made entirely of stainless steel to a certain height.

The nougat

raw material, which is ready for use in the syrup usage tank, comes to the

nougat cooking machine (seidomat) to be cooked There are actuator valves

on the Seidomat boiler in order to receive the product in a controlled manner.

There is a

chimney outlet that can be controlled by an actuator valve on the boiler and a

vacuum pump on the side of the chassis in order to discharge the unwanted gases

formed during cooking on the Seidomat. The vacuum pump can be connected

directly to the sewer.

Seidomat boiler, turbomixer,

chassis and pipes are made of stainless steel material in order to be

completely suitable for food.

Turbomixer is used to fluff

the product cooked with superheated steam in seidomat. There are stainless

mixers in the turbomixer to homogenize the product. Embossing is done under a

certain pressure.

EGG SOLUTION TANK AND SCRAMBLER MIXER

The egg solution tank is used to mix the egg product and make it ready for use in the turbomixer. It is mixed continuously with the stainless anchors in this tank to maintain its homogeneity. The outer part of the egg solution tank is cold-walled. The cold wall prevents the egg from spoiling. The egg solution tank is completely made of stainless steel material.

EGG SOLUTION REST TANK

This tank is used to disappear egg foam and make the solution rest. The

outer part of the egg solution tank is cold-walled. The cold wall prevents the

egg from spoiling. There is a pump for transfer. It is made of stainless steel.

OILY MIXTURE AND SCRAMBLER MIXER

The liquor tank serves to mix the oily mixture product and make it ready

for use in order to be used in the solid mixer. It is mixed continuously with

the stainless anchors in this tank to maintain its homogeneity. It is produced

cambered to facilitate the flow of the product in the lower part of the boiler.Liquor

tank and beater mixer, mixer parts, chassis and transfer pipes are all made of

stainless steel material.

POWDERED SUGAR MILL

This machine is used for prepearing powdered sugar to use cocolate

producing. There is stainless steel chamber on the machine to pour sugar in it.

It consist of two pin groups, one is stable and the other is dynamic. The

stable pin group can easily disassemble. It provides covenience maintence and

cleaning.

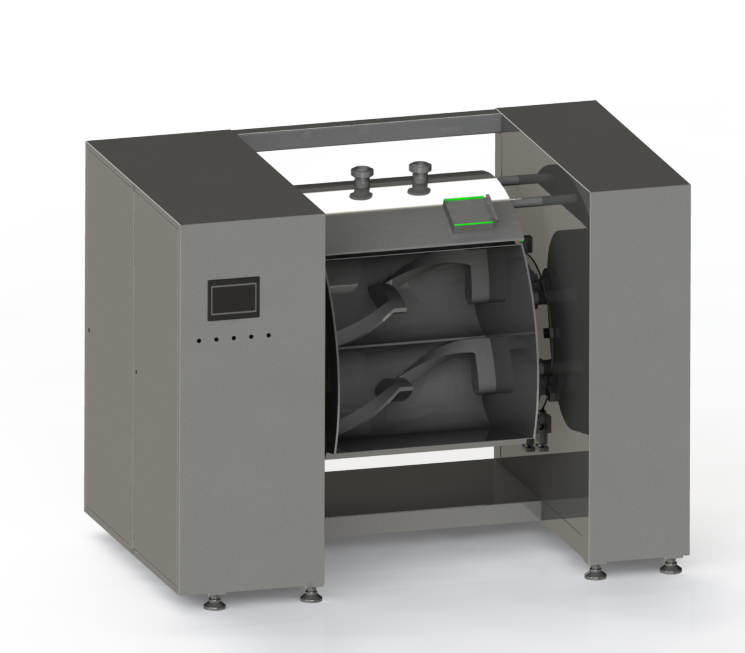

Z- MIXER (SOLİD MIXER)

The solid mixer is the machine used

to mix the nougat product homogeneously before laying it in the nougat

cylinders.

The solid mixer bowl is made of stainless material suitable for food. The

hopper is tilted to empty the product by means of the electric motor. The

anchors are controlled by two separate motors