CARAMEL KITCHEN

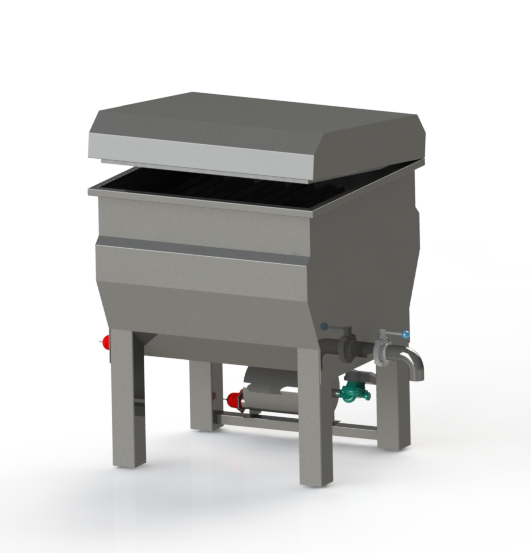

MİLK SOLUTION TANK AND SCRAMBLER MIXER

The milk solution tank is used to mix the milk and make it

ready for use in order to be used in the pre-preparation tank in caramel

production. It is mixed continuously with the stainless anchors in this tank to

maintain its homogeneity. It is produced cambered to facilitate the flow of the

product in the lower part of the boiler.Milk solution tank and beater mixer,

mixer parts, chassis and transfer pipes are all made of stainless steel

material.

FAT MELTER

The fat melting machine is

used for melting solid fats for use in caramel production. There is a serpentine in which hot water is circulated to

melt the oil in the chamber. The outside of the chamber is heat-walled.

PRE-PREPARATION TANK

Pre-preparation tank is the boiler where all the raw

materials are collected and homogeneously mixed to prepare the caramel product.

It is completely made of 304 chrome stainless steel.

CARAMEL COOKİNG BOİLER

The caramel product, which is ready to be cooked in the

pre-preparation tank, is cooked in this machine. Cooking is done with

superheated steam. The outside of the chamber is double wall. While there is

superheated steam on the first wall, the second wall is insulated..All parts of

caramel cooking boiler are made of stainless chrome matereial.

CARAMEL USEGE TANK

The caramel

product coming from the caramel boiling is taken to the caramel usage tank to

be used. The caramel usage tank is completely made of stainless chrome

material. There is a motor that drives the mixers on it. The chamber is

heat-walled.